FableFive: Peggy Healy Stearns, Lead Software Designer for Fab@School Maker Studio

Teacher, software designer, and maker movement enthusiast, those are three ways to describe Dr. Peggy Healy Stearns. She's also the lead software designer behind FabMaker Studio, FableVision Learning's new digital/3D Fabrication program for the classroom. And she's no stranger to the classroom, in fact you could say that is where it all began.

"In 1983, when I was teaching 8th grade, I touched my first computer. It was like magic," Peggy said. "I immediately saw the potential and knew I wanted to design software. I bought an Apple IIe, learned to program, and headed to graduate school to earn my doctorate and start my software design career."

For this month's FableFive, Peggy shared a bit about her background in software design, her role in the Maker Movement, and of course Fab@School Maker Studio

1) How did you get connected with FableVision?

While designing my first software programs for Sunburst Communications, I worked as a district technology coordinator and taught at the University at Buffalo. In 1991, I brought my idea for a program called The Graph Club to Tom Snyder Productions (TSP). That’s when I met Peter H. Reynolds, then TSP’s Vice President and Creative Director. Peter designed the graphic interface for The Graph Club and we worked together on collaborative activities based on a mystery theme. Peter wrote his first published book, Fizz and Martina’s Incredible Not-for-Profit Pet Resort, as part of the original Graph Club curriculum. I went on to design Neighborhood MapMachine, Community Construction Kit, Diorama Designer, and Rainforest Designer, and then came back to Peter with the design for a program called Stationery Studio. By then, Peter and his twin brother Paul had founded FableVision. The first version of Stationery Studio was released in 2003 and a new enhanced version in 2010.

2) How did the Fab@School Maker Studio Journey Begin?

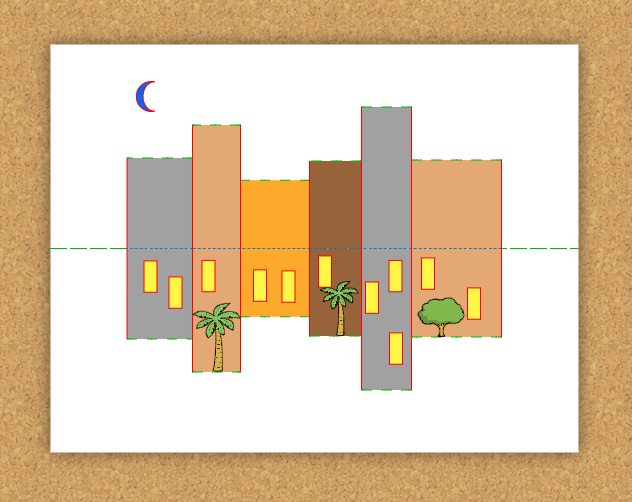

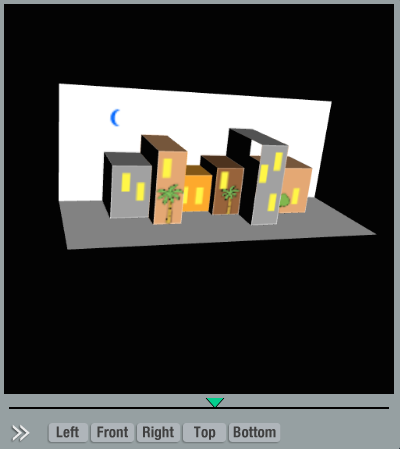

In 2008, Glen Bull at the University of Virginia was exploring how 3D printers and inexpensive digital cutters could support STEM education. When Glen came across my software programs, Community Construction Kit and Diorama Designer, he realized these programs addressed similar concepts, except kids cut by hand instead of using electronic cutters. Glen asked me to design onramp software for the Fab@School coalition, which sought to establish the curriculum, instructional resources, software, professional development, and research to support the use of digital design and fabrication in STEM education. I asked Peter and Paul to collaborate on the development of what came to be Fab@School Maker Studio. Since then, the Fab@School collaborative has grown to include multiple school districts, Canon, SITE, the Smithsonian, the FabFoundation, TIES, and other partners.

3) How do you see the Maker Movement impacting the classroom?

The Maker Movement, a powerful example of hands-on project-based learning, has tremendous potential to positively impact the classroom. Making stuff is intrinsically motivating and gives students the opportunity to explore, invent, problem solve, discover, and apply what they’ve learned in an immediate and meaningful context. Making is not so much about the product, but the process, and how children are empowered to construct their own learning. Curiosity and discovery are natural by-products and fuel further explorations and discovery.

Maker projects, like real life, tend to be cross-curricular, so learning takes place in a richer, more meaningful environment. Although we think of the Maker Movement primarily in terms of STEM and STEAM, maker projects offer rich opportunities to integrate multiple curricular areas. When students make things, they have something concrete and of personal interest to talk about and develop language skills in a meaningful context. The Smithsonian Invention Kits go a step further and incorporate history, culture, and consumer science.

The University of Virginia’s preliminary research suggests that these maker projects positively impact measurable learning outcomes.

4) What are some simple ways for schools to create a Maker Space?

Maker spaces don’t have to be hi-tech. You can start with Legos, K’NEX, cardboard, tape, yarn, markers, scissors, and other readily accessible materials. First, create an attractive and inviting space where students feel free to explore, create, collaborate, and invent. Create a culture where mistakes are not only acceptable but understood as a critical part of the process.

In terms of digital design, the big buzz has been about 3D printing. We suggest an affordable, accessible onramp – paper and card stock. With just Fab@School Maker Studio and a single electronic cutter for under $150, students can create pop-ups, 3D models, working machines, and even the Smithsonian Invention Kits. Some projects can be cut by hand, so no cutter is required.

5) What has been your favorite moment working on Fab@School and what is your favorite project to fabricate?

December 2009: Paul made the leap of faith and committed FableVision to the Fab@School journey and Maker Studio development. At that point, few people had heard of 3D printing or even digital design and fabrication, and almost no one saw it’s potential in the classroom. Peter and Paul had faith in the vision and jumped on board this unique creative journey.

Also, Fall 2015, Paul personally took charge of Maker Studio development and brought Andrea Calvin on board, our new FableVision Learning Vice President. Our dream team, with John Lechner, Bill Norris, and Adam Landry, turbo-charged the project and readied Fab@School Maker Studio for release.

Now for my favorite project to fabricate, I like projects with moving parts. I believe they’re not only more motivating, but also provide more opportunities for learning across the curriculum. Projects with moving parts can be simple pop-ups or more involved like an automaton and the curriculum-rich Smithsonian Invention Kits being developed at the University of Virginia.